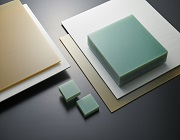

Types and Characteristics

From general cloth phenol laminate sheets to glass laminate sheets, we produce laminate sheets with various characteristics and widespread applicability in many fields, with thorough quality control and comprehensive technology. Since these products have high reliability in mechanical strength, they are also applied to the tank supports of LPG tankers.

| Base material used | Characteristics | |||

| Cloth base | Glass base | |||

| Resin used | Phenol resin | Phenol resin | The standard laminate sheet, used for electrical/electronic equipment parts. It has high machinability and is inexpensive. | |

|---|---|---|---|---|

| ― | Epoxy resin | This has excellent mechanical strength, electrical characteristics, and humidity resistance and is suitable for places exposed to and high pressure and with a requirement for high mechanical strength. An FR-4 grade is also available. | ||

Cloth Base Laminate Sheets

| Part No. | PFP-461 | PRC-463 | ||

|---|---|---|---|---|

| JISK6912 Reference standard |

PL-FCM | PL-FLE | ||

| NEMA Reference standard |

C | LE | ||

| Base material | Cloth | |||

| Resin | Phenol | |||

| Flatwise breakdown voltage | MV/m | C-90/20/65 | 5 - 10 | 11 - 15 |

| Insulation resistance | MΩ | C-90/20/65 | 5×101 - 103 | 103 - 105 |

| Bending strength | MPa | A FW-LW | 140 - 200 | 140 - 180 |

| Compressive strength | MPa | A FW | 220 - 270 | 260 - 330 |

| Izod impact strength |

J/cm | A EW-CW | 1.2 - 1.5 | 0.8 - 1.3 |

| Burning resistance (Material Combustion Test for Railroad Vehicles) |

- | A | - | |

| Specific gravity | - | A | 1.3 - 1.4 | |

| Application | For general electrical and mechanical requirements |

|||

*The values above are measured values, not certified values.

*JIS certification and NEMA certification have not been obtained.

Glass Base Laminate Sheets

| Part No. | PGP-640 | PGE-6635 | PGE-6674 | PGE-6771 | |||

|---|---|---|---|---|---|---|---|

| JISK6912 Reference standard |

PL-GH | EL-GEM | EL-GEH | EL-GEH | |||

| NEMA Reference standard |

G-3 | G-10 | G-11 | G-11 | |||

| Base material | Glass | ||||||

| Resin | Phenol | Epoxy | |||||

| Flatwise breakdown voltage | MV/m | C-90/20/65 | 20 - 25 | 20 - 30 | 20 - 28 | 20 - 30 | |

| Insulation resistance | MΩ | C-90/20/65 | 104 - 106 | 106 - 108 | |||

| Bending strength | MPa | A FW-LW | 380 - 460 | 400 - 500 | 400 - 500 | ||

| Compressive strength | MPa | A FW | 450 - 600 | 400 - 500 | 450 - 550 | ||

| Izod impact strength |

J/cm | A EW-CW | 5 - 7 | 5 - 6 | |||

| Burning resistance (Material Combustion Test for Railroad Vehicles) |

- | A | ― | Extreme incombustibility at 5 mm or more |

Extreme incombustibility at 3 mm or more |

― | |

| Specific gravity | - | A | 1.70 - 1.95 | 1.75 - 1.95 | 1.75 - 1.95 | 1.85 - 2.00 | |

| Application | For general electrical requirements, high strength, and heat resistance |

||||||

*The values above are measured values, not certified values.

*JIS certification and NEMA certification have not been obtained.